IMC

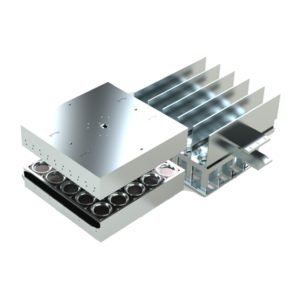

Doganay Mould specializes in the production of high-quality thermoforming moulds, catering to the unique needs of various industries. Our company prides itself on a team of skilled engineers and experienced specialists, all dedicated to precision and excellence. Each thermoforming mold is crafted with attention to detail and commitment to quality, ensuring a robust and efficient production process.